America's Premier Log Home Company

Experience Satterwhite Living

Satterwhite Log Homes produces top quality log homes for homeowners who enjoy beauty that only nature can deliver. Satterwhite homes are made with nature's finest logs, sourced from dead standing timber

When you build a Satterwhite log home, you build your dream home.

Your Home. Your Way

We Build It

We provide the materials and labor. Our experienced crews will dry-in your new home — Constructed Shell.

You Build It

We supply a package of materials necessary to dry-in your home: house logs, framing lumber, plywood, doors, windows, and more.

Logs Only

You build it. House logs are the essential ingredient of any log home. Satterwhite will sell you the necessary footage of house logs, sealant, and screws needed to erect your log walls.

Why Satterwhite

Experience the Satterwhite Difference

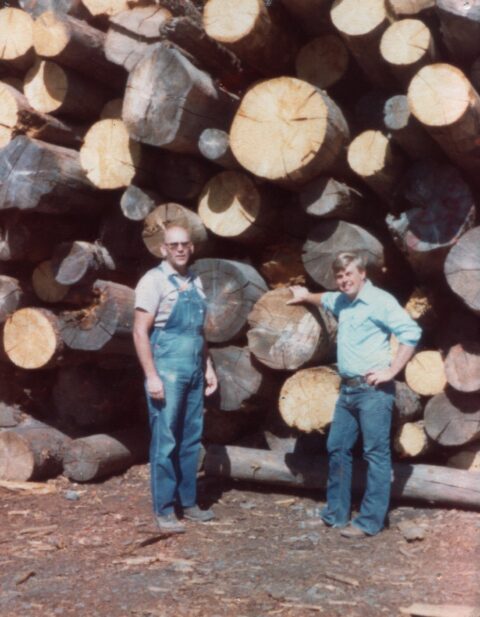

Satterwhite searches North America and beyond for unique character woods. Produced by small sawmills from sustainable sources, these beautiful materials are in limited supply and almost never offered by national retailers. Even so, character woods from Satterwhite are competitively priced.

Satterwhite house logs are made from trees killed by natural causes. Sourced primarily from U.S. National Forests in the American West, these trees dry thoroughly over time in arid environment. We avoid cutting green or living trees. Not only is the right thing to do for the environment, we feel dead standing timber is the finest product you can use for the long term performance of your log home.

Come Visit Us

Gunnison, Utah

- 911E Hwy 89 N

- Gunnison, UT 84634

Ellijay, Georgia

- 14378 GA-515

- Ellijay, GA 30536

Longview, Texas

- 8405 US-259

- Longview, TX 75605

What Our Customers Say

Satterwhite Log Homes are the best. They are a sound product and sealed tight against the elements. We have a lot of room under the roof of our home and the great room is outstanding. You feel like you are outside. We have the walk-around porch on the home, which makes it great on rainy days.

Put simply, this place knows logs! Very knowledgeable staff and absolutely no sales pressure. Allowed time for shopping and answered every question I had. I am pleased that TMC Construction recommended Satterwhite.

My first experience with Satterwhite was in the mid-1980s, when my family built a home in East Texas. 35 years later, the house is still beautiful and has stood the test of time. Now my wife and I are making plans to build one of our own. We wouldn't consider any other option - only Satterwhite! Great people.

Bought a previously owned, 1 owner, Satterwhite home-FANTASTIC! The previous owner had not maintained the home but it was still solid. Slight maintenance needed to bring it back to full beauty, but SOLID! Satterwhite staff in Longview, Texas were wonderful and helped with info on needed supplies to bring her back to her pristine beauty. Very well built homes. We love our home and are the envy of all our friends. You can't go wrong with a Satterwhite Home!

Outstanding design, delivery and set-up construction for our gorgeous log home. We cannot compliment this staff enough, especially our salesman, Jeff McKinney. I'd adopt him if possible. Although some designs are more complicated than ours, it didn't matter. We were treated as if we were their most important customer. Their seminars are outstanding, and their follow-up after construction is second to none.

Couldn't ask for nicer people to work with from the planning stage to the final nail driven stage! Even now, if I have a problem and I have been in my home for several years (I had what turned out to be a simple window sash problem, and they gladly walked me through it), I can still call them, and they still help me! Satterwhite is a company that has employees that care about you even AFTER THE SALE!!

We built our home in 2004. The home is still as beautiful as the day we built it. Satterwhite was so easy to work with, and they did everything they said they would do. We would recommend them to everyone.

I have used you guys twice now, and I have no complaints. 100% Excellent customer service and quality material. I do log home restoration and these guys were on the ball making sure my logs look good. I had all the material I needed and kept in direct contact with me. I highly recommend them.

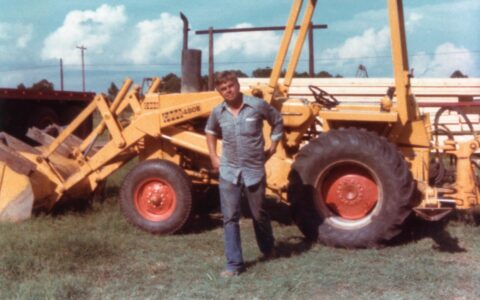

A+ Reputation of Trust

We earn our A+ reputation of trust every day, and we've been doing so for almost 50 years. Customers who choose Satterwhite Log Homes experience log home living at its best.

Celebrating 50 Years

About Satterwhite Log Homes